Construction, engineering, and product design materials are no longer chosen just for strength. They are selected for flexibility, sustainability, efficiency, and how well they adapt to creative ideas. Among all modern metals, aluminium has quietly become a backbone of innovation, lightweight yet strong, versatile yet durable.

Behind many of these innovations lies a manufacturing process that turns raw metal into smart, functional shapes used in buildings, transport, electronics, and more. This article explores how thoughtfully engineered aluminium solutions are transforming industries, why they matter, and how businesses can use them to build smarter and faster.

Why Aluminium Has Become a Designer’s Favorite

Aluminium didn’t earn its popularity overnight. It gained trust because it solves multiple problems at once.

First, it is lightweight, which makes transportation easier and reduces structural load. Second, it offers an excellent strength-to-weight ratio, meaning it performs well without unnecessary bulk. Third, aluminium resists corrosion naturally, making it suitable for both indoor and outdoor applications.

Beyond physical properties, aluminium is also highly recyclable, aligning perfectly with global sustainability goals. These qualities together make aluminium a natural choice for industries that value efficiency and long-term performance.

The Manufacturing Process That Unlocks Versatility

What truly sets aluminium apart is how it can be shaped. Through advanced forming techniques, manufacturers can create precise cross-sections that serve both functional and aesthetic purposes.

This is where aluminium extrusion profiles play a crucial role. By pushing heated aluminium through a specially designed die, manufacturers achieve consistent shapes with tight tolerances. These shapes can be simple or highly complex, depending on the application.

The result is a component that is ready to perform whether it needs to support weight, house electrical systems, or enhance visual appeal.

How Different Industries Use Custom Aluminium Shapes

Construction and Architecture

Modern buildings rely heavily on aluminium for window frames, curtain walls, railings, and facades. The clean lines and slim profiles support contemporary design trends while maintaining structural integrity.

Architects prefer aluminium because it allows freedom in design without compromising safety. Custom sections can be developed to match specific project requirements, reducing on-site modifications.

Transportation and Mobility

From rail coaches to electric vehicles, aluminium components help reduce overall weight, improving fuel efficiency and performance. Lightweight frames and structural supports contribute directly to sustainability goals in transportation.

Electrical and Electronics

Aluminium is an excellent conductor of heat, making it ideal for heat sinks, enclosures, and frames. Precisely formed profiles allow better airflow, improved cooling, and safer operation of electronic systems.

Industrial and Modular Systems

Factories and warehouses often rely on modular aluminium systems for workstations, safety guards, and automation frames. These systems are easy to assemble, modify, and expand, saving both time and cost.

Design Freedom Without Compromising Strength

One of the biggest advantages of custom aluminium components is the ability to integrate multiple functions into a single shape. A well-designed section can act as a support, a cable channel, and a mounting surface at the same time.

This reduces the need for additional parts, lowers assembly time, and improves overall product reliability. When designed correctly, aluminium extrusion profiles can significantly simplify complex structures.

Manufacturers with strong design teams help clients optimize shapes early in the development phase, avoiding costly redesigns later.

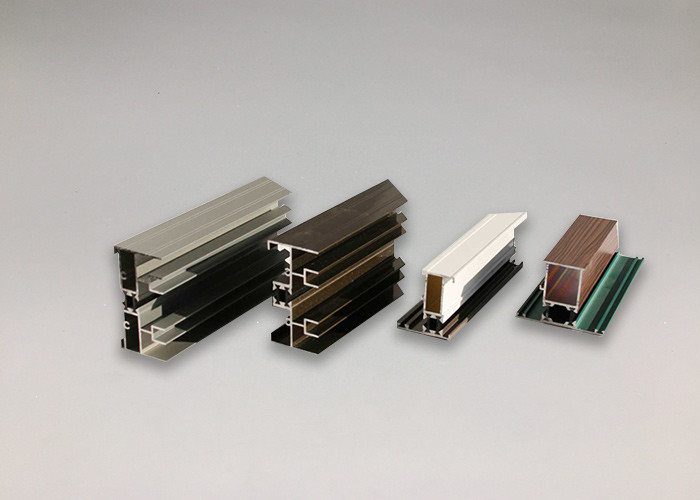

Surface Finishes That Add Performance and Appeal

Aluminium doesn’t stop at shape, it can also be finished to meet different performance and aesthetic needs.

Common finishing options include:

- Anodizing for corrosion resistance and a premium look

- Powder coating for color consistency and durability

- Mill finish for industrial applications where appearance is secondary

These finishes extend the lifespan of aluminium products and allow them to blend seamlessly into different environments, from luxury interiors to harsh industrial settings.

Sustainability: A Material Built for the Future

Sustainability is no longer optional. Aluminium stands out because it can be recycled repeatedly without losing its properties. Recycling aluminium consumes far less energy compared to producing new metal, reducing environmental impact.

Many manufacturers now integrate renewable energy into their operations, further lowering the carbon footprint. Choosing aluminium solutions is not just a technical decision, it’s an environmental one.

What to Look for in a Reliable Aluminium Partner

Not all aluminium manufacturers are the same. The right partner brings more than machinery, they bring expertise.

Here’s what businesses should prioritize:

- In-house design and tooling support to customize solutions

- Consistent quality control for reliable performance

- Scalable production capacity to meet growing demand

- Industry experience across multiple applications

A great manufacturer stands out by combining technical know-how with a deep understanding of real-world applications, helping clients move from concept to execution smoothly.

The Future of Aluminium in Design and Engineering

As industries move toward lighter, smarter, and more sustainable solutions, aluminium will continue to evolve. Innovations in alloy development, precision tooling, and automated manufacturing are expanding what’s possible.

Advanced aluminium extrusion profiles will play an even bigger role in smart buildings, renewable energy systems, electric vehicles, and modular construction. The material’s adaptability ensures it will remain relevant for decades to come.

As technology and infrastructure continue to evolve, these profiles will increasingly support integrated systems such as smart facades, solar mounting structures, lightweight battery enclosures, and flexible modular frameworks. Their ability to combine strength, precision, and design flexibility allows engineers and architects to respond quickly to changing performance standards and sustainability goals, making aluminium a long-term enabler of innovation rather than just a material choice.

Conclusion

Great products and structures are built on smart material choices. Aluminium offers the rare combination of strength, flexibility, sustainability, and design freedom. When paired with the right manufacturing expertise, it becomes a powerful tool for innovation.

For businesses seeking dependable, high-quality aluminium solutions backed by engineering support and industry experience, JM Aluminium continues to be a trusted name. To explore their capabilities and approach, visiting them can offer valuable insight into how modern aluminium solutions are shaped for tomorrow.

JM Aluminium brings together advanced manufacturing capabilities, in-house design expertise, and a deep understanding of diverse industry requirements to deliver reliable aluminium solutions at scale. With a strong focus on precision, quality control, and customized development, the company works closely with clients to transform functional concepts into durable, performance-driven aluminium components suited for long-term use across construction, industrial, and infrastructure applications.